CNC Machining: Reworking Fashionable Manufacturing with Precision and Automation

CNC Machining: Reworking Fashionable Manufacturing with Precision and Automation

Blog Article

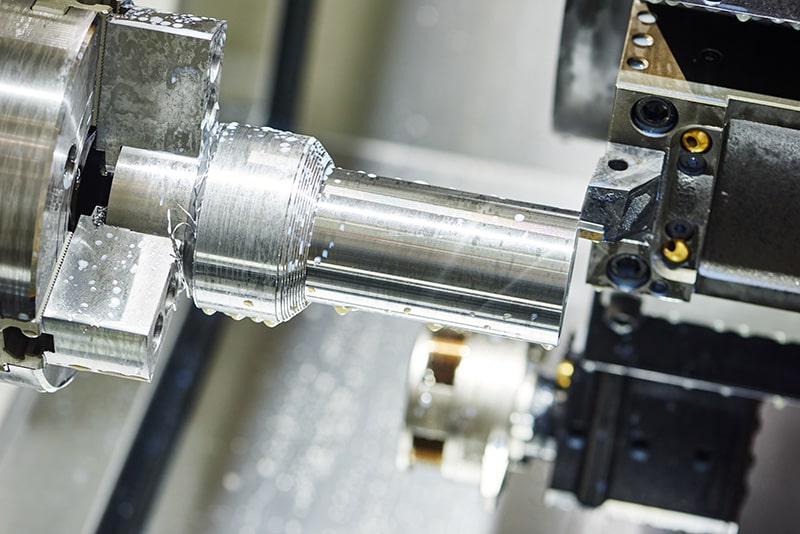

CNC machining is one of the most innovative technologies of contemporary manufacturing. It fundamentally alters the way industry produces components and parts, offering a level of accuracy, precision and a range of applications that are unmatched by traditional methods. CNC machining employs computerized control as well as machinery to complete operations like cutting drilling, milling and grinding of materials that range from metals and plastics to composites and wood. Automating manufacturing processes, CNC machining eliminates many of the inefficiencies and inconsistencies related to manual operation. As a result, you get a system that produces highly accurate parts at faster speeds as well as with more consistency, driving innovation in industries such as aerospace and consumer electronics.

What lies at the heart of CNC machine is the capability to transform digital drawings into actual parts. Using computer-aided design (CAD) software engineers and designers can create detailed 3D models of the wanted part. Digital designs are converted into precise commands, or "G-code," which the CNC machine follows to perform tasks like cutting, drilling, or milling. This control is digital, which allows for a high level of precision which manual machining cannot achieve. Also, after a design is programed in the machine it can be repeated with perfect consistency, producing identical pieces in large amounts without manual adjustments. This repeatability is essential in industries where precision and uniformity are crucial.

One of the major advantages of CNC machining is its versatility to work with a vast variety of different materials. If manufacturers have to deal with metallic materials like steel and titanium, or soft materials such as wood or plastic CNC machines are adjusted to deal with a variety of cutting and shaping tasks. This adaptability is what makes CNC machine-making suitable for the production of components in a range of sectors including medical equipment and aerospace components, to automobile parts and consumer electronics. Being able to process complex geometries with tight tolerances has also made CNC manufacturing the best method to create intricate pieces that would be difficult and even unattainable to manufacture using traditional techniques.

CNC machines' versatility is a further reason that it has become the foundation of manufacturing today. This technology is compatible with a wide range of different materials, ranging from tough metals such a titanium or stainless steel to wood and plastics. This means that CNC machining is suited to make parts suitable for a variety of industries, for example aerospace, automotive electronics, medical, and consumer products. Additionally, CNC machines can perform a range of operations, like cutting, milling engraving, drilling and even 3D contouring, all in one setup. This versatility eliminates the necessity for multiple machines and part transfers, thereby increasing the productivity. When it comes to making prototypes or manufacturing large volumes of components, CNC machining offers the capability to cater for a wide range of needs in production. To gather extra information please look at Premiumparts

As well as the speed and accuracy, CNC machining is valued due to its economic efficiency, and especially when producing large production runs. After the initial set-up and programming of the machine are completed, producing additional parts requires minimal input, reducing overall production costs. If you are a manufacturer working with costly material like aerospace-grade alloys CNC manufacturing reduces waste through making the cutting process more efficient, making sure that each piece is made with the least amount of losses in material. This precision and efficiency ensure that CNC the ideal tool for prototyping, as well as large-scale production, as it allows producers to test quickly and tweak designs with minimal production cost.

Another obstacle in CNC machining lies in the programing and setting of CNC machines. Although CNC machines remove a lot of the manual work involved during the production process however, they require experienced techs to develop and then input the required programs. These technicians must have expertise in CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software and understand the specific machining requirements of each project. Mistakes in programming can result in defective components, wasted materials, and the machine being down for a long time. In addition, initial set-up of the machine could be time-consuming, especially for complicated projects that need numerous tools or operation. But once the machine is correctly installed and programed, it can produce parts in a remarkably fast time and precision which reduces the chance of error-prone runs in the future.